IRON MAKING

IMP main equipment comprise of a 36m2 Sintering Machine, 100m2 Sintering Machine, a 200m2 Sintering Machine, a 600m3 Blast Furnace and a 1380m3 Blast Furnace.

Raw material yard capable of storing over 800,000 tons of raw materials, fuels and auxiliary materials.

Loading System of blast furnace adopts a series of tank-type bell top charging system which able to achieve circular multi-layer material distribution, and the furnace is equipped with an imaging system and a furnace temperature measuring device.

Air supply system is equipped by an axial flow blower unit with adjustable full vane BPRT residual pressure booster.

Pulverized Coal Injection System is obtain 2 set of vertical medium speed coal mill for coal injection in blast furnace.

STEELMAKING

Currently our capacity is 2.7 million tons / year.

The main equipment comprises a 600-ton Mixed Furnace, 2 unit of 80-ton Converter Furnace, a 80-ton Ladle Furnace, 2 unit of Single-Strand Slab Continuous Casting Machine , a Six-Strand Square/Round Billet Continuous Casting Machine, casting hoist and total 27 unit of bridge cranes.

OG system and dust bag are used for the first and second dedusting of blown converter.

Hot Metal Pretreatment System is able to remove the impurities such as sulfur from the molten iron.

4 unit of 5m*7m*5m slag pool are able to process 300 thousand tons of slag per year.

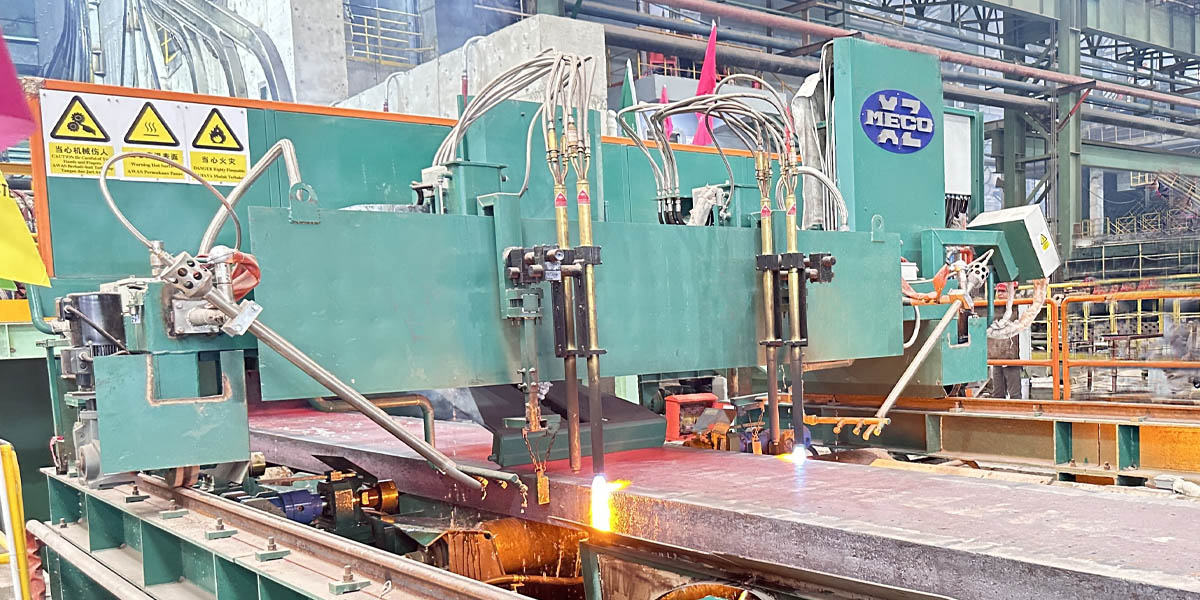

ROLLING MILL

There are 2 existing reheating furnaces (with space reserved for a third), a four-high reversible roughing mill, a flying shear (with space reserved for a hot coil box), seven four-high finishing mills, and two coilers (with space reserved for a third).

Equipped with various large-scale instruments, including a width gauge, speed gauge, thickness gauge, multifunctional gauge, flatness gauge, and surface inspection gauge, enabling comprehensive quality monitoring.

Both the roughing and finishing mills are equipped with dedicated dust removal systems to ensure a clean working environment.

Equipped with four strapping machines and one automatic marking machine to effectively reduce labor intensity.

Equipped with a dual-cyclone filter and an integrated pressurized system to improve water quality and promote resource recycling.

COKE ENERGY

Coke energy main equipment currently comprise of 8 Clean Type Heat Recovery Coke Oven with production capacity of 800,000 tons / year.

1 unit of 100t/h Coke Dry Quenching (CDQ) System and suppoting equipments.

4 unit of 67.5t/h HT SHP Waste Heat Recovery Boilers. The waste heat wll proceed by 2-unit 50MW generator unit.

A raw material yard capable of storing 100,000 tons of raw materials.

2x800T/D Double-Shaft Maerz Lime Kilns to provide lime for sintering and steelmaking process.

POWER ENERGY AND AUXILIARY

Power energy and auxiliary plant possess High Voltage Distribution System, Oxygen Making System, Fuel Gas System, Power Generation System and etc.

High Voltage Distribution System includes a 275/33KV substation and 3 units of 90MVA main transformer.

Oxygen Making System includes a 10000m3/h and 30000m3/h Air Separation Unit and able to sell liquid oxygen, nitrogen and argon.

A 50 thousand m³ of converter gas holder.

Power generation system consist of 1 unit 55MW steam turbine generator unit, 2 unit 50MW steam turbine generator unit and 2 unit 190t/h gas fired boilers.

PORT LOGISTICS

2 Belt Conveyor and 3 Tubular Belt Conveyor total about 8 KM is connect between Kemaman Port and ESSB.

Raw materials and fuels transport directly from Kemaman Port to ESSB Closed Integrated Stockyard directly through enclosed tubalar belt convetor. It can prevent pollution from particular and dust flying from raw material.